Assembly

References

Customer: Strabag, Háje asphalt mixing plant

Customer: Strabag, Háje asphalt mixing plant

Realization: 04/2020

Place: Háje, Czech Republic

Order: Repair and grinding of the drying drum supporting ring

Characteristics of the order: The client has demanded us to repair a ”repaired” supporting ring which exhibited a so-called “thousand edge” and the drum in operation exhibited large vibrations and “jumped”. We made a gradual correction of the thousand edges to a smooth surface and modified the drum support structure; after our grinding the drying drum has not exhibited any vibrations both unloaded and loaded and its operation has been set to a smooth run.

Customer: Redecam, Fincementi cement plant (CRH)

Customer: Redecam, Fincementi cement plant (CRH)

Realization: 10/2019 - 04/2020

Place: Pargas, Finland

Order: Retrofitting 2 electrofilters to one bag filter including a replacement of an exhaust fan and a new exhaust piping

Characteristics of the order: The order has involved disassembly of substations, cutting-off of upper parts of the both filters, disassembly of electrodes from the both filters, modification of the foul chamber, its reinforcement, assembly of the upper frame, manufacture and installation of new filter cloths and a penthouse. Disassembly of the old exhaust fan including the inlet and outlet conduit as far as the stack. Installation of a new exhaust fan including a new damper and complete piping as far as the stack.

Parameters: Weight of the installed new equipment 150 t

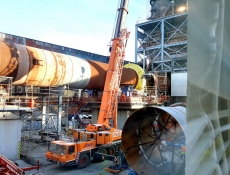

Customer: Českomoravský cement (Heidelberg), Mokrá

Customer: Českomoravský cement (Heidelberg), Mokrá

Realization: 01/2020 - 02/2020

Place: Mokrá cement plant, Czech Republic

Order: Replacement of the support shell and supporting ring including replacement of the tread on the axial pulley and installation of a new housing of the ring gear

Characteristics of the order: The order has involved the kiln survey, specification of the cutting point, the shell cut-off, disassembly of the old support part including the supporting ring, disassembly of the axial pulley, renovation of the axial pulley. Re-installation of the axial pulley, fitting the supporting ring onto the kiln support part and their installation to the kiln, setting the kiln to its position and welding.

Parameters: Weight of the installed new equipment 101 t

Customer: LB Cemix, Kotouč Štramberk production plant

Customer: LB Cemix, Kotouč Štramberk production plant

Realization: 08/2018 - 04/2019

Place: Štramberk, Czech republic

Order: Installation of a double-shaft kiln line for lump lime burning and other accessories, the manufacture and installation of machinery for the kiln and a milled coal storage silo

Characteristics of the order: The commencement of the works was delayed due to building works, nevertheless, we succeeded to quicken the scheduled works to the end of 2018. On-site we assembled and welded the main body of the kiln and service platform, a sector staircase tower and bridges to particular levels.

After the New Year the assembly of platforms was finished and a super-structure above the kiln was fitted with insulation sound-protection walls.

Besides the very kiln, equipment for material feeding was assembled as well, i.e. a skip elevator and a distribution movable container with guide chutes. Discharge tables and a system of sealing valves and unloading vibration conveyors were finished, too.

In a blower room we installed 8 blowers and a compressor for actuating air and a hydraulic station. On the blower room roof we installed a process filter made by our company, with technological piping and a stack. A carrying structure for the milled coal silo with a capacity of 350 tons was installed behind the kiln.

Parameters: Weight of the installed equipment 600 tons

Customer: Lhoist WE

Customer: Lhoist WE

Realization: 10/2018 - 03/2019

Place: Nameché town, near Namur city, Belgium

Order: Manufacture, delivery and installation of 200 t of technologies, in particular piping

Characteristics of the order: Complete assembly including the manufacture of dedusting equipment during normal operation, including installation of tunnels and jacketing.

Customer: CEMEX Czech Republic s.r.o.

Customer: CEMEX Czech Republic s.r.o.

Realization: 02/2019

Place: Prachovice, Czech republic

Order: Replacement of 2 parts of a shell of the largest kiln in the Czech Republic (inner Ø 5.6m) including a supporting ring of 80 t

Characteristics of the order: Installation of two pieces of a kiln shell with an inner diameter of 5.6 m. The first part of the shell was replaced including a supporting ring that was put on the supporting shell and centered according to required tolerances during preassembly. A total weight of the part with the supporting ring was 135 tons. From this reason the largest mobile crane in the Czech Republic with a capacity of 700 tons was used.

The project was highly demanding due to a short deadline, only 14 days for the complete replacement. Particular parts of the shell were replaced step by step, the shell with the supporting ring was replaced first. Welding of joints on each of the shells was carried out on both the joints at the same time. Both the parts were replaced successfully, thanks to the perfect centering the total run-out of the kiln was reduced substantially. There was no work safety problem for the whole time of the replacement, all uplifts were carried out without any complications according to pre-specified procedures.

Customer: DOOSAN LENTJES GmbH

Customer: DOOSAN LENTJES GmbH

Realization: 07/2018 - 02/2019

Place: Kjopsvik, Norway

Order: Installation of 200 t of steel structures, assembly of 100 t of RFP technologies and 100 t of piping

Characteristics of the order: Installation of a system for flue gas desulphurization using sea water. Works were carried out in highly difficult climatic conditions, Kjopsvik town is located more than 700 km beyond the Northern polar circle. At the same time, we had to meet very strict legislative conditions applicable in Norway.

The installation was carried out during the normal operation in the cement plant; we performed particularly the installation of the steel structure, piping and FRP technology delivered to Doosan company.

Customer: Českomoravský Cement a.s.

Realization: 11/2018 - 02/2019

Place: Radotín, Czech Republic

Order: Disassembly of the existing roof superstructure and installation of a new hall of 33 t on silos, including jacketing

Characteristics of the order: Installation and handling at a height of 35 m above the ground. With regard to demandingness of the work we used 220 t crane from MZP. The structure was assembled from smaller parts on the ground and joined together on the silos using the crane of 220 t. A console part of the structure, standing outside the silos, was welded to plates inserted in a concrete upstand that was also built by MZP company.

Parameters: Amount of assembled tons of a steel structure 33 t, a used mobile crane 220 t

Customer: ANDRITZ Oy, Finland

Customer: ANDRITZ Oy, Finland

Realization: 10/2018 - 11/2018

Place: Štětí, Czech Republic

Order: 583 tons of demounted and newly installed technology of a kiln line for lime burning; used mobile cranes – 750 t, 220 t, 100 t

Characteristics of the order: Replacement of three parts of a lime kiln shell and an entire drive of the kiln.

The main part of the project was a replacement of 3 parts of a lime kiln shell and an entire drive of the kiln, which was the biggest challenge of the whole project because an extremely short time period was left for this scope of works. All deadlines were met. In spite of the fact that the works were performed under significant time pressure no occupational accident occurred and commencement of the line operation after the shut-down was started according to the planned time schedule.

Some of the works were performed in concurrence of building works, which increased demandingness and emphasized the continuous coordination of the entire project. The replacement of the kiln shell parts was so difficult also for the fact that the inlet (c. 8 tons) and discharge (65 tons) parts of the kiln are placed inside buildings and this demanded accurate calculations of crane uplifts.

Customer: Valmet Technologies, Inc.

Customer: Valmet Technologies, Inc.

Realization: 09/2017 - 09/2018

Place: Copenhagen, Denmark

Order: Installation of 2269 tons of conveyance routes, technologies and platforms.

Characteristics of the order: Installation of conveyor bridges including the assembly of conveyors and technologies. The entire project was oriented on double lifts (using two cranes), where some lift heights reached over 40 metres, therefore large mobile cranes had to be used. No failure as to the occupational safety occurred during the entire period of construction process and all uplifting was carried out without any complications and within the deadlines pre-set by us.

Customer: LAB SA

Customer: LAB SA

Realization: 01/2018 - 06/2018

Place: Thiverval-Grignon, France

Order: Installation of 287 tons of steel structures and 188 tons of technology

Characteristics of the order: Installation of a new filtration unit including technologies and conveyors, pipelines and side walkways. The installation was performed in confined spaces with a great cooperation with other companies that were working in the premises and around. The installation was carried out using a tower crane.

Customer: CEMEX Cement, k.s.

Customer: CEMEX Cement, k.s.

Realization: 01/2018 - 04/2018

Place: Prachovice, Czech republic

Order: A replacement of CM1 cement mill including demounting the existing technology and the manufacture of the mill

Characteristics of the order: The main benefit for the customer was the fastness of the mill replacement and the cost saving owing to the assembly method (no need to build a costly transport track for the entire mill and to demount the millhouse steel structure).

All the tasks were fulfilled and the technology was successfully installed without any accident.

The project was successfully completed and handed over to the customer for regular operation on 18/5/2018.

Parameters: A disassembly of a cement ball mill with a weight of 500 tons. A manufacture of a cement mill with a weight of 450 tons. An installation of a ball mill with a weight of 450 tons, including an assembly of a modern ring gear.

Customer: KAWE AG

Customer: KAWE AG

Realization: 02/2018 - 03/2018

Place: Rzesow, Poland

Characteristics of the order: Installation of a new industrial conveying drying system, our own manufacture and installation of side walkways. The installation was completed a week before the scheduled date.

Customer: Lafarge Cement a.s.

Customer: Lafarge Cement a.s.

Realization: 01/2018 - 03/2018

Place: Čížkovice, Czech Republic

Order: 281 tons of demounted and newly assembled technology

Characteristics of the order: Reconstruction of the dedusting system of a kiln line and mill facility in Lafarge – Čížkovice cement plant.

A condition for the reconstruction was to preserve a sheath of the existing three-chamber electro-filter and to design a new filter as the so-called hybrid filter – i.e. the first chamber remains as an electro-filter and the second and third one is re-built as a hose filter, which ensures enhancement of separability of the filter and improves the quality of the medium outletting to the air.

The first chamber of the filter was fully reconstructed as an electro-filter, the second and third chamber was equipped with over 1800 hoses with a length of 9 m made of high-temperature resistant fabric as a following filtration element. Aside from the filter reconstruction we also delivered and installed other auxiliary equipment.

Despite of the complicated conditions we succeeded to finish the works, so that the technology could commence the operation in time. All functional tests were successful and the following full operation proves high reliability of the line, maintaining the specified output parameters and a high degree of cleaning of the outletting medium.

Customer: Českomoravský cement, a.s.

Customer: Českomoravský cement, a.s.

Realization: 01/2018 - 02/2018

Place: Mokrá, Czech Republic

Order: Replacement of a 12 m long rotary kiln

Characteristics of the order: Within the scope of technological equipment repairs a replacement of a 12 m long rotary kiln was performed. The replacement demandingness lied in a complete replacement of a kiln shell including a supporting ring and an outlet segment.

The heaviest part had a weight of 80 tons and the assembly was carried out by our largest crane with a lifting capacity of 400 tons.

Parameters: replacement of a kiln part on III – c. 110 tons

Customer: Vápenka Čertovy schody a.s. (lime plant)

Customer: Vápenka Čertovy schody a.s. (lime plant)

Realization: 05/2017 - 08/2017

Place: Tmaň, Czech Republic

Order: Disassembly and assembly of the kiln filter technology and 2 pcs of shaft flaps FMS (MAERZ shaft kiln)

Characteristics of the order: Disassembly of technological equipment of a filter, 75 t weight + assembly of technological equipment of a new filter, 105 t weight

Customer: Metsä Fibre Oy

Customer: Metsä Fibre Oy

Realization: 05/2016 - 05/2017

Place: Äänekoski, Finland

Order: Installation and commissioning of 3 lines of technological equipment and 3 pcs of wood chip storage equipment

Characteristics of the order: Installation and commissioning of 3 lines of technological equipment for processing of tree trunks into wood chips (spruce, pine, birch), installation and commissioning of 3 pcs of wood chip storage equipment and welding of 3 pcs of debarking drum shells.

Parameters: Cranes with load-carrying capacity of 300 t and 500 t

Customer: Andritz Oy

Customer: Andritz Oy

Realization: 09/2016 - 01/2017

Place: Timrå, Sweden

Order: Installation of new technological equipment

Characteristics of the order: Installation of new technological equipment into the existing building (green liquor filters and their equipment, conveyors, polymer tanks, pumps, agitators, steel structures, conveying lines, centrifugal machines)

Parameters: Realization – 13 workers + PM; 30 t, 100 t cranes

Customer: Cement Hranice a.s.

Customer: Cement Hranice a.s.

Realization: 01/2017 - 01/2017

Place: Hranice na Moravě, Czech Republic

Order: Repair of a part of a rotary kiln on the 3rd base

Parameters: 70 t weight - 7.7 m length, 4.4 m diameter

Customer: Aliacem s.r.o (A-TEC)

Customer: Aliacem s.r.o (A-TEC)

Realization: 10/2016 - 12/2016

Place: Mannersdorf, Austria

Order: Exchanger reconstruction

Characteristics of the order: - Assembly of new additional steel structures of the exchanger – 358 t

- Assembly of the 1st stage of a new calcining channel – 111 t

- Strengthening of the existing exchanger steel structures – 62 t

- Disassembly of the existing technology (cyclones, a calcining channel, chutes for raw materials, a calcining chamber, a part of a tertiary piping system) and service platforms - approximately 250 t

- Assembly of the 2nd stage of the calcining channel – 55 t

- Assembly of other technological elements (cyclones, chutes for raw materials, a part of a tertiary piping system) – 117 t

- Assembly of new service platforms, strengthening and modifications of the existing exchanger steel structures – 75 t

Customer: Vápenka Čertovy schody a.s.

Customer: Vápenka Čertovy schody a.s.

Realization: 01/2015 - 12/2016

Place: Tmaň, Czech Republic

Order: Installation of a shaft kiln, stair tower and related frameworks and technological equipment

Characteristics of the order: Installation of a shaft kiln, a storage silo for lignite multi-dust, a stair tower for the lignite multi-dust storage silo, related steel frameworks and technological equipment ensured by the client

Parameters: Total weight of the assembly: 1081 t, 62035 work-hours were needed for this installation in total

Customer: Aalborg Portland

Customer: Aalborg Portland

Realization: 02/2016 - 03/2016

Place: Aalborg, Denmark

Order: Disassembly and follow-up assembly

Characteristics of the order: Disassembly and follow-up assembly of a part of piping from cyclones to ventilators’ ID (2 lines), a tertiary elbow (with a lining) and expansion joints; insulation of new components

Parameters: Realization – 18 workers; 130 t, 30 t, cranes, a truck fitted with an arm

Customer: Metso Minerals, France

Customer: Metso Minerals, France

Realization: 08/2014 - 05/2015

Place: Franzefoss, Norway

Order: Assembling of manufacturing technology

Characteristics of the order: Installation of a new crushing and screening plant and belt conveyors

Customer: Boldrocchi, S.r.l., Italy

Customer: Boldrocchi, S.r.l., Italy

Realization: 12/2013 - 03/2015

Place: Hannover, Germany

Order: Manufacturing, transport, installation and replacement of an electrofilter with a bag filter

Characteristics of the order: Replacement of an electrofilter with a bag filter; manufacturing, transport and installation of a new filter, pipelines, service platforms and walkways, accessories and insulation

Parameters: 25 workers + PM; 350 t, 250 t, 130 t, 30 t cranes

Customer: Progress OK, a.s.

Customer: Progress OK, a.s.

Realization: 06/2014 - 09/2014

Place: Žďas, a.s., Žďár nad Sázavou, Czech Republic

Order: Installation of 2 pcs of polymer and water tub

Parameters: Order volume - CZK 0.9 mil

Customer: Boldrocchi, S.r.l., Italy

Customer: Boldrocchi, S.r.l., Italy

Realization: 12/2013 - 07/2014

Place: Degerhamn, Sweden

Order: Installation of a new dedusting system and walkway

Characteristics of the order: Installation of a new dedusting system (kiln and cooler line: filters, pipelines, a cooler, dedusting and powdering lines), installation of an extra walkway between a kiln filter and a chimney.

Parameters: 12 workers; 300 t, 45 t cranes

Customer: KOMA-Industry s.r.o.

Customer: KOMA-Industry s.r.o.

Realization: 05/2014 - 07/2014

Place: ArcelorMittal Ostrava a.s., Czech Republic

Order: Repair of TZ rotary wagon discharger

Parameters: Order volume - CZK 3.4 mil

Customer: Gen. supplier: ČKD PRAHA DIZ, a.s. for: ZVVZ MACHINERY, a.s., PREST Přerov a.s.

Customer: Gen. supplier: ČKD PRAHA DIZ, a.s. for: ZVVZ MACHINERY, a.s., PREST Přerov a.s.

Realization: 10/2013 - 11/2013

Place: SYNTOS Kralupy, a.s., Kralupy nad Vltavou, Czech Republic

Order: Installation of exhaust ducting and combustion chamber

Parameters: Order volume - CZK 4.3 mil

Customer: PT Indocement Tunggal Prakarsa, Tbk. Heidelberg Technology Center: Indonesia Branch

Customer: PT Indocement Tunggal Prakarsa, Tbk. Heidelberg Technology Center: Indonesia Branch

Realization: 06/2013 - 09/2013

Place: Jakarta, Indonesia

Order: Supervision of mill steel structures and transportation routes installation

Parameters: Order volume - CZK 1.5 mil

Customer: Tereos TTD, a.s.

Customer: Tereos TTD, a.s.

Realization: 07/2013

Place: Dobrovice, Czech Republic

Order: 2 pcs of dryer supporting circles grinding

Parameters: Order volume - CZK 0.5 mil

Customer: Lafarge Cement, a.s.

Customer: Lafarge Cement, a.s.

Realization: 12/2012 - 04/2013

Place: Čížkovice, Czech Republic

Order: Calciner KKN reconstruction, cement plant Čížkovice

Parameters: The order volume - CZK 13.9 mil

Customer: Precheza a.s.

Customer: Precheza a.s.

Realization: 07/2012 - 11/2012

Place: Přerov, Czech Republic

Order: Erection of a steel structure and a spraying chimney

Parameters: The order volume - CZK 6 mil

Customer: Tereos TTD, a.s.

Customer: Tereos TTD, a.s.

Realization: 09/2012

Place: Dobrovice, Czech Republic

Order: Erection of a chimney, Dobrovice sugar plant

Parameters: The order volume - CZK 2.3 mil

Customer: Holcim Česko a.s.

Customer: Holcim Česko a.s.

Realization: 03/2011

Place: Prachovice, Czech Republic

Order: Replacement of a rotary kiln shell, Prachovice cement plant

Parameters: The order volume - CZK 1.3 mil

Customer: Cement Hranice a.s.

Customer: Cement Hranice a.s.

Realization: 01/2010 - 02/2010

Place: Hranice, Czech Republic

Order: Replacement of a rotary kiln shell, Hranice cement plant

Parameters: The order volume - CZK 3.1 mil

Customer: Mondi Štětí a.s.

Customer: Mondi Štětí a.s.

Realization: 01/2010 - 02/2010

Place: Štětí, Czech Republic

Order: Debarking drum repair, Štětí paper-mill

Parameters: The order volume - CZK 2.7 mil

Customer: Cement Hranice a.s.

Customer: Cement Hranice a.s.

Realization: 08/2009 - 09/2009

Place: Hranice, Czech Republic

Order: Replacement of a cement mill shell, Hranice cement plan

Parameters: The order volume - CZK 1 mil

Customer: Metso Paper

Customer: Metso Paper

Realization: 04/2009 - 08/2009

Place: Ružomberok, Slovak Republic

Order: Installation of a debarking drum, Ružomberok paper-mill

Parameters: The order volume - CZK 3.3 mil

Customer: Metso Minerals

Customer: Metso Minerals

Realization: 10/2007 - 12/2008

Place: Pont Charron, Canada

Order: Installation of a crushing plant tertiary part, Pont Charron crushing plant

Parameters: The order volume - CZK 9.3 mil

Customer: Redecam s.r.I. Italy

Customer: Redecam s.r.I. Italy

Realization: 2006 - 2007

Place: Grand River, Italy

Order: Installation of a filter, Grand River cement plant

Parameters: The order volume - CZK 19.2 mil

Customer: Redecam s.r.I. Italy

Customer: Redecam s.r.I. Italy

Realization: 2005 - 2006

Place: Italy

Order: Installation of a dust cooler, Black River lime plant

Parameters: The order volume - CZK 8.2 mil

News

BENVIG Company Acquisition

The shareholders of company Montaze Prerov a.s. together with other investors aquired company BENVIG ...

Read more »

Loading and transport of a dryer for SWISS COMBI – W. Kunz dryTec AG

On 23/4/2020 loading and transport of a dryer for our customer SWISS COMBI – W. Kunz dryTec AG was ...

Read more »

Joing of strong Group MULTICRAFT

In the beginning of year 2020 Montaze Prerov a.s. has become part of strong group of companies called ...

Read more »

Technology Matters of Interest

- We have developed a unique system for large rotary objects handling without the use of cranes which is advantageous particularly in existing buildings.

- We perform reconditioning of pulleys and supporting rings of rotary equipment just during the operation with the aid of grinding.

Contacts

Montáže Přerov a. s.

9. května 3303/119

750 02 Přerov

Assembly:

Pavel Hrdina

+420 581 267 361

+420 724 209 738

hrdina[at]montaze.cz