About us

References

Today our installations and customers can be found in about 30 countries worldwide, among them for example:

- USA

- Canada

- Great Britain

- France

- Italy

- Germany

- Finland

- Sweden

- Russia

- India

- Brazil

- ... and many others

One of our significant achievements is a direct cooperation with cement and lime industry market leaders, as e.g. Lafarge, Holcim, Heildelberger cement, Buzzi Unicem, Lhois, Carmeuse or with leading world’s technology suppliers as e.g. Metso, CPT, Doosan etc.

You can find detailed information on the realized projects in sections of the respective activities of our company:

Customer: Redecam, Fincementi cement plant (CRH)

Customer: Redecam, Fincementi cement plant (CRH)

Realization: 10/2019 - 04/2020

Place: Pargas, Finland

Order: Retrofitting 2 electrofilters to one bag filter including a replacement of an exhaust fan and a new exhaust piping

Characteristics of the order: The order has involved disassembly of substations, cutting-off of upper parts of the both filters, disassembly of electrodes from the both filters, modification of the foul chamber, its reinforcement, assembly of the upper frame, manufacture and installation of new filter cloths and a penthouse. Disassembly of the old exhaust fan including the inlet and outlet conduit as far as the stack. Installation of a new exhaust fan including a new damper and complete piping as far as the stack.

Parameters: Weight of the installed new equipment 150 t

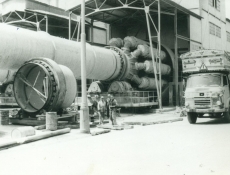

Customer: Českomoravský cement (Heidelberg), Mokrá

Customer: Českomoravský cement (Heidelberg), Mokrá

Realization: 01/2020 - 02/2020

Place: Mokrá cement plant, Czech Republic

Order: Replacement of the support shell and supporting ring including replacement of the tread on the axial pulley and installation of a new housing of the ring gear

Characteristics of the order: The order has involved the kiln survey, specification of the cutting point, the shell cut-off, disassembly of the old support part including the supporting ring, disassembly of the axial pulley, renovation of the axial pulley. Re-installation of the axial pulley, fitting the supporting ring onto the kiln support part and their installation to the kiln, setting the kiln to its position and welding.

Parameters: Weight of the installed new equipment 101 t

Customer: LB Cemix, Kotouč Štramberk production plant

Customer: LB Cemix, Kotouč Štramberk production plant

Realization: 08/2018 - 04/2019

Place: Štramberk, Czech republic

Order: Installation of a double-shaft kiln line

Characteristics of the order: Installation of a double-shaft kiln line for lump lime burning and other accessories, the manufacture and installation of machinery for the kiln and a milled coal storage silo.

Parameters: Weight of the installed equipment 600 tons

Customer: DOOSAN LENTJES GmbH

Customer: DOOSAN LENTJES GmbH

Realization: 07/2018 - 02/2019

Place: Kjopsvik, Norway

Order: Installation of 200 t of steel structures, assembly of 100 t of RFP technologies and 100 t of piping

Characteristics of the order: Installation of a system for flue gas desulphurization using sea water. Works were carried out in highly difficult climatic conditions, Kjopsvik town is located more than 700 km beyond the Northern polar circle. At the same time, we had to meet very strict legislative conditions applicable in Norway.

The installation was carried out during the normal operation in the cement plant; we performed particularly the installation of the steel structure, piping and FRP technology delivered to Doosan company.

Customer: ANDRITZ Oy, Finland

Customer: ANDRITZ Oy, Finland

Realization: 10/2018 - 11/2018

Place: Štětí, Czech Republic

Order: 583 tons of demounted and newly installed technology of a kiln line for lime burning; used mobile cranes – 750 t, 220 t, 100 t

Characteristics of the order: Replacement of three parts of a lime kiln shell and an entire drive of the kiln.

The main part of the project was a replacement of 3 parts of a lime kiln shell and an entire drive of the kiln, which was the biggest challenge of the whole project because an extremely short time period was left for this scope of works. All deadlines were met. In spite of the fact that the works were performed under significant time pressure no occupational accident occurred and commencement of the line operation after the shut-down was started according to the planned time schedule.

Some of the works were performed in concurrence of building works, which increased demandingness and emphasized the continuous coordination of the entire project. The replacement of the kiln shell parts was so difficult also for the fact that the inlet (c. 8 tons) and discharge (65 tons) parts of the kiln are placed inside buildings and this demanded accurate calculations of crane uplifts.

Customer: Valmet Technologies, Inc.

Customer: Valmet Technologies, Inc.

Realization: 09/2017 - 09/2018

Place: Copenhagen, Denmark

Order: Installation of 2269 tons of conveyance routes, technologies and platforms.

Characteristics of the order: Installation of conveyor bridges including the assembly of conveyors and technologies. The entire project was oriented on double lifts (using two cranes), where some lift heights reached over 40 metres, therefore large mobile cranes had to be used. No failure as to the occupational safety occurred during the entire period of construction process and all uplifting was carried out without any complications and within the deadlines pre-set by us.

Customer: Metsä Fibre Oy

Customer: Metsä Fibre Oy

Realization: 05/2016 - 05/2017

Place: Äänekoski, Finland

Order: Installation and commissioning of 3 lines of technological equipment and 3 pcs of wood chip storage equipment

Characteristics of the order: Installation and commissioning of 3 lines of technological equipment for processing of tree trunks into wood chips (spruce, pine, birch), installation and commissioning of 3 pcs of wood chip storage equipment and welding of 3 pcs of debarking drum shells.

Parameters: Cranes with load-carrying capacity of 300 t and 500 t

Customer: Aliacem s.r.o (A-TEC)

Customer: Aliacem s.r.o (A-TEC)

Realization: 10/2016 - 12/2016

Place: Mannersdorf, Austria

Order: Exchanger reconstruction

Characteristics of the order: - Assembly of new additional steel structures of the exchanger – 358 t

- Assembly of the 1st stage of a new calcining channel – 111 t

- Strengthening of the existing exchanger steel structures – 62 t

- Disassembly of the existing technology (cyclones, a calcining channel, chutes for raw materials, a calcining chamber, a part of a tertiary piping system) and service platforms - approximately 250 t

- Assembly of the 2nd stage of the calcining channel – 55 t

- Assembly of other technological elements (cyclones, chutes for raw materials, a part of a tertiary piping system) – 117 t

- Assembly of new service platforms, strengthening and modifications of the existing exchanger steel structures – 75 t

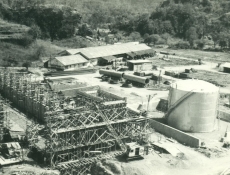

Customer: Vápenka Čertovy schody a.s.

Customer: Vápenka Čertovy schody a.s.

Realization: 01/2015 - 12/2016

Place: Tmaň, Czech Republic

Order: Installation of a shaft kiln, stair tower and related frameworks and technological equipment

Characteristics of the order: Installation of a shaft kiln, a storage silo for lignite multi-dust, a stair tower for the lignite multi-dust storage silo, related steel frameworks and technological equipment ensured by the client

Parameters: Total weight of the assembly: 1081 t, 62035 work-hours were needed for this installation in total

Customer: Metso Minerals, France

Customer: Metso Minerals, France

Realization: 2012

Order: Manufacturing of a stone washer and discharge hoppers with Hardox lining

Customer: Claudius Peters, France

Customer: Claudius Peters, France

Realization: 2012

Order: Manufacturing of belt conveyors and a stacker and reclaimer for a crushing plant

Parameters: 160 tons and 480 tons

Material: S235 and S355

Customer: Raumaster, Finland

Customer: Raumaster, Finland

Realization: 2011

Order: Manufacturing of machinery for material conveying systems

Customer: Lafarge Cement, a.s.

Customer: Lafarge Cement, a.s.

Realization: 12/2009 - 02/2010

Place: Čížkovice, Czech Republic

Order: Replacement of front faces of a cement mill, cement plant Čížkovice

Customer: REDECAM, Italy

Customer: REDECAM, Italy

Realization: 2005 - 2010

Place: USA - Pittsburgh

Order: Dedusting of a clinker rotary kiln

Characteristics of the order: For several years manufacturing and delivery of dust filters including pipelines to countries: Cement plant Le Havre, France; Lime plant Black River, Cinncinaty, KY, USA; Lime plant Grand River, OH, USA; Pittsburgh, PA, USA for Buzzi, Saint Louis,MO, USA; Cement plant Radotín, Czech Republic; Lime plant Mokrá u Brna, Czech Republic; Košice, Slovakia; Karlstadt, Germany

Customer: LHOIST Groupe

Customer: LHOIST Groupe

Realization: 2010

Place: Portugal

Order: Manufacturing of equipment for a kiln line, transportation to the site and installation

Customer: Swiss Combi, Switzerland

Customer: Swiss Combi, Switzerland

Realization: 2010

Place: Switzerland

Order: Manufacturing of pipeline parts and modules for exhaust of combustion products

Customer: Mondi a.s.

Customer: Mondi a.s.

Realization: 2009

Place: Ružomberok, Slovak Republic

Order: Installation of a debarking drum

Customer: Norskstein AS

Customer: Norskstein AS

Realization: 2009

Place: Norway

Order: Crushing and screening equipment with a storage facility

Customer: VICAT

Customer: VICAT

Realization: 2009

Place: France

Order: Disassembly and installation of a rotary kiln supporting ring

Customer: Hyundai

Customer: Hyundai

Realization: 2007

Place: Nošovice, Czech Republic

Order: Erection of a forging shop building

Customer: Metso Minerals

Customer: Metso Minerals

Realization: 2007

Place: Pont Charron, Canada

Order: Installation of a tertiary part of a crushing plant

Customer: REDECAM, Italy

Customer: REDECAM, Italy

Realization: 2006

Place: Italy

Order: Installation of a filter - cement plant Grand River, Italy

Customer: Sugar plant

Customer: Sugar plant

Realization: 2005

Place: Němčice na Hané, Czech Republic

Order: Lime plant disassembly

News

BENVIG Company Acquisition

The shareholders of company Montaze Prerov a.s. together with other investors aquired company BENVIG ...

Read more »

Loading and transport of a dryer for SWISS COMBI – W. Kunz dryTec AG

On 23/4/2020 loading and transport of a dryer for our customer SWISS COMBI – W. Kunz dryTec AG was ...

Read more »

Joing of strong Group MULTICRAFT

In the beginning of year 2020 Montaze Prerov a.s. has become part of strong group of companies called ...

Read more »

Contacts

Montáže Přerov a. s.

9. května 3303/119

750 02 Přerov

+420 581 267 111

+420 606 958 091

+420 581 267 318

montaze[at]montaze.cz